Power cable allows to transmit electricity from substations to utility, industrial, public facilities. Wire construction consists of wires, insulating coating, outer sheath, armor, shield. Products are divided into classes according to the type of alloy, structure and structure, the number of conductors, the intensity of the current flow, etc.

Content

Variety of products

The purpose of power wires is to transmit electricity to residential buildings, public organizations, industries. Products are classified according to the parameters and characteristics of cables, internal wires, sheaths, etc.

External (external) protection from atmospheric precipitation and changing weather conditions in cables for electrical wiring can be armored or unarmored. A control cable differs from a power wire in less strength, because has no reinforcement.

According to the constructive solution of the current-carrying cores the products are subdivided into single-core cables or cables with 2-5 wires (multi-core).

Classification according to the voltage strength divides the cables into those intended for operation under pressure:

- low;

- medium;

- high.

Products differ in total weight and weight of individual elements (insulation, conductors, shields).

Popular and sought-after designs of power cable include types:

- PPV;

- APPV;

- VVG;

- PVS;

- Vbbshv;

- NUM;

- KG.

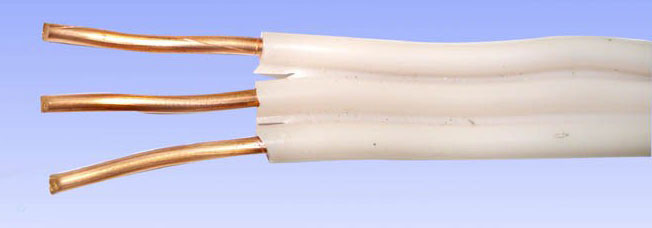

PPV cable consists of a copper core (three-core) protected by a layer of PVC. Products are used for indoor lighting. Products should be fixed statically.

APPV wire is made mainly of aluminum alloys; the material runs along the length of the wire.

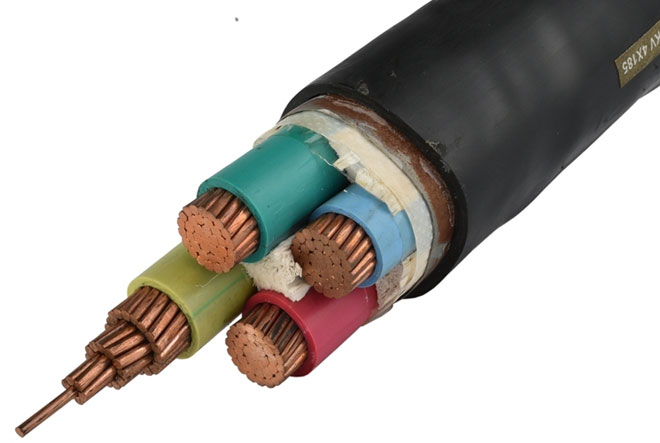

The core of VVG cable consists of copper, has 1-4 cores. The protective coating consists of PVC. Cables are used for lighting lines in residential and public complexes with different air temperature and humidity.

Copper in the composition of PVS wire provides plasticity of construction. According to the thickness of the product is allowed 2-5 twist parts of the rod. Wires are used in household appliances, lighting systems, adapters.

In Vbbshv cables, up to 5 twisting of the cores is provided. The products are used in conducting power transmission lines. The products are notable for strength and durability.

NUM wire has outer sheath of non-combustible material, 2-4 inner cores. These wires are optimal for electric wiring. The advantage of the products is resistance to deformation; the design withstands temperature fluctuations from -50 to +50 ° C.

As part of the cable brand KG - multi-wire cores of copper. The protective layer consists of a rubberized insulator. The strength, ductility, moisture resistance of products allow the products to be used in difficult areas.

The concept of cores in electrical wiring

The design of power cables includes plastic conductors made of metal alloys. The core can be single-wire or multi-wire. The configuration of the element cross-section (flat, sector) varies. An important characteristic is the cross-sectional area of the conductor.

Conductive and neutral grounding cores

Conductors can be either current carrying or grounding (neutral) in accordance with their designation.

Conductive core is the main element in the cable. The core can consist of 1-5 wires. Shape of the elements according to the standards is round, segment or sector type. Products are regulated by the type of cross-section and diameter.

Zero conductors are used at uneven loads of the power grid. Grounding strands are characterized by small cross-section and are placed in the center of the wire. Elements ensure safe operation.

Wire insulation

The conductors in the wires must be insulated with a special coating.

The protective raw materials used are:

- paper;

- rubber;

- plastic.

Paper insulation involves applying layers to the conductors and impregnation of raw materials with a flame retardant compound. Products are used on equipment operating under high voltage.

Rubber insulating coating is plastic, strong, durable. Rubber-coated conductors are used in cables for connection to devices that are moved during operation. It is necessary to take into account the sensitivity of rubber to minus temperatures. To prevent deformation, cores are supplemented with polyvinylchloride coating.

Insulating layer made of plastic (polyethylene or polyvinylchloride) is budgetary, reliable, has high insulation, long service life.

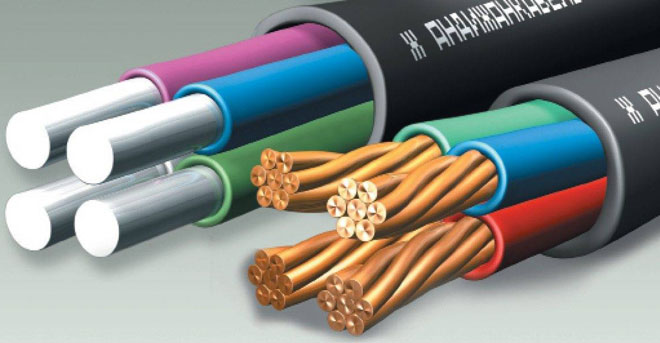

Single-core and multi-core

Power cable design includes wires:

- single-core;

- multi-core.

A single-core wire includes 1 current conductor. The products are used in public buildings, residential complexes to supply electricity. In production facilities, single-core wires are used for power output from generators to the general network.

Multicore wires consist of several interwoven wires. In order to increase plasticity, a thread is stretched between the wires. These wires are highly resistant to vibration, are flexible and can be used to connect household appliances.

Material of the core

For the manufacture of cores are used different types of raw materials (aluminum alloys, copper, steel). Combined compositions and synthetic core materials are allowed. To pass optical signals the wires are made of plastic or glass. Cores made of nichrome are used for heat dissipation.

Copper

Copper wires are made flexible or rigid according to the manufacturing process. The diameter of single-wire elements is 16-95 mm², multi-wire - 25-800 mm². The conductors with a rigid structure have a circular cross-section. Copper alloys are efficient, reliable, durable, but expensive.

Aluminum

Aluminum wires have a large cross-sectional area, have a small electrical conductivity. Wires are soft, prone to deformation, oxidation, require regular checks of the reliability of connections in the electrical system. Conductors made of aluminum alloys have a rigid structure. Cross-sectional area of wires should not exceed 1 mm². In residential installations, aluminum conductors must have a cross-sectional area of at least 16 mm².

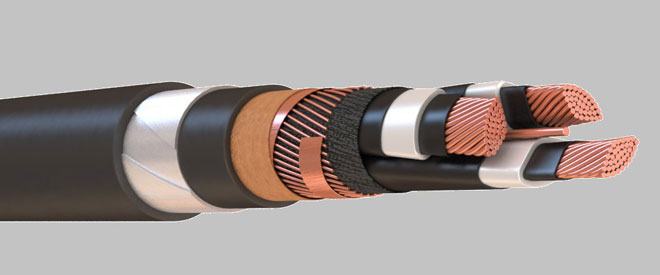

Shields, fillers, and sheaths

The design of a power cable includes the mandatory layers between the insulation:

- shields;

- fillers;

- sheaths;

- protective coatings.

Shields are designed to protect the outer layers from electromagnetic effects. The elements are made of foil, paper treated with a special composition.

Fillers are made in the form of bundles of plastic, rubber, paper tapes. The elements allow you to adjust the tightness of the adjacency of parts of the construction. Compounds make the product hermetic and resistant to mechanical impacts, give it the necessary shape.

The shells are designed to protect the wire surfaces. Parts of the structure are made of aluminum alloys, lead, non-combustible plastic and rubber. The surfaces can be smooth or corrugated. Sheaths prevent deformation of the wire from water and acid-alkaline compositions.

Protective covers (cushion, armour) are the finishing touches in the construction. Armor made of galvanized tapes and wires makes the product durable.

Power cable insulation

Power cable sheathing is designed to insulate products from outside building elements. The coating should not conduct current.

The main types of cable insulation are represented by coatings:

- of paper with impregnation;

- made of durable rubber;

- of polyvinyl chloride;

- polyethylene.

Polystyrene, fluoroplastic, magnesium oxide, etc. can be used as insulation.

Designs of cables covered with paper sheets with aluminum and lead sheathing are optimal for passing electric power with voltage of 35 kV (GOST 18410-73). Aluminum-coated insulation materials are not recommended for production sites with the use of alkaline solutions. Lead-coated insulation protects from aggressive-alkali environments.

Cables with external rubber insulation are suitable for installation of electrical networks with DC voltage up to 10 kV. Wires are used in circuits with different levels of electric wiring (GOST 433-73). The products are notable for high hygroscopicity and plasticity. Wire construction is equipped with a durable steel armor, which prevents deformation.

Polyvinylchloride insulated cables are designed to perform electrical wiring with a rated voltage of 0.66-6 kV (GOST 16442-80). The materials are budget-friendly and plastic. When using additives, the composition becomes resistant to minus or elevated temperatures.

External insulating jacket of cross-linked polyethylene (XLPE) is an advanced composition, characterized by low weight, durability, resistance to moisture, heat resistance.

Polyethylene is designed according to the density for voltage:

- Group 1 (6-35 kV);

- 2 group (45-150 kV);

- 3 group (220-330 kV).

According to shape

The cross-sectional configuration of the cable in the section can be:

- sectoral;

- round unsealed;

- round sealed;

- segmented, etc.

Flat power cable is designed for industrial premises with dry and humid air, outdoor structures, overpasses. Products with a circular cross-section are designed for stationary electrical installations inside buildings.

Service life

Cable service life is regulated by the state standards (GOST 16442-80, GOST 18410-73, etc.) and is divided into actual and warranty.

The warranty for the product is given by the manufacturer for the period counted from the beginning of the usage of the construction. The order is valid if the buyer observes the rules of transportation, laying, operation. The warranty on cables with plastic insulation is at least 5 years. For cables with paper insulation, a warranty of up to 4.5 years is given.

Service life of a cable is the actual period of use of the structure up to the technical parameters permitted by the standard. The actual duration and period of use is about 25 years for plastic-insulated cables. Wires insulated with impregnated paper can be used for up to 30 years.

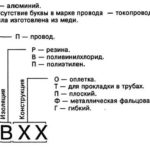

Marking as a means of determining the type of cable

Features of application and composition of wires are reflected in the marking code.

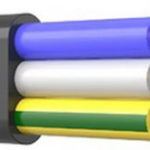

Regulations adopted the marking of cables using different shades of insulation and conductor bars:

- brown and black colors denote the core of the phase;

- blue tint is used to denote the neutral conductors;

- grounding cores are marked in yellowish-green tone, etc.

Provided marking with a letter code (PPV, APPV, VVG), which is applied to the label or product and fixes what the product consists of.

The following symbols indicate the types of insulation of power cables:

- P (polyethylene);

- H (non-flammable rubber);

- B (polyvinyl chloride);

- P (rubber), etc.

Marking rules are fixed in GOST 18620-86.

In conclusion, I would like to add that power cables are transported wound on special wooden or plastic drums, as well as coiled in coils.

Related articles: